Explosion-proof LED Bay Light

Technical Data

| Model No. | Power | Ta | Input Voltage | Lumen | Efficacy |

CCT

|

CRI

|

Driver

|

Emerg. Time

|

|

TL-EX-20W-B2

|

20W |

65°C

|

AC100-277V/ DC12-48V |

2,800lm | 140lm/W |

2200K-

7000K

|

>70

|

External

emergency

driver

|

90min. / 180 min. (optional) |

|

TL-EX-40W-B2

|

40W | 55°C | 5,600lm | ||||||

|

TL-EX-60W-B

|

60W |

40°C

|

AC100-277V/ AC200-480V/ DC12-48V |

8,400lm |

Internal

emergency

driver

|

||||

|

TL-EX-80W-B

|

80W | 40°C | 11,200lm | ||||||

|

TL-EX-100W-B3

|

100W | 40°C | 14,000lm | ||||||

|

TL-EX-120W-B3

|

120W | 55°C | 16,800lm | ||||||

|

TL-EX-150W-B3

|

150W | 50°C | 21,000lm | ||||||

|

TL-EX-200W-B3

|

200W | 40°C | 28,000lm | ||||||

|

TL-EX-250W-B4

|

250W | 40°C | 35,000lm | ||||||

|

TL-EX-300W-B4

|

300W | 40°C | 42,000lm | ||||||

|

TL-EX-350W-B4

|

350W | 40°C | 49,000lm | ||||||

|

TL-EX-400W-B4

|

400W | 40°C | 56,000lm |

Certifications

Marking ATEX

II 3 G Ex ec IIC T6...T3 Gc

II 2 D Ex tb IIIC T85°C...T103°C Db

Marking IECEx

II 3 G Ex ec IIC T6...T3 Gc

II 2 D Ex tb IIIC T85°C...T103°C Db

Ex ec IIC T6...T3 Gc

Ex tb IIIC T85°C...T100°C Db

UL844 Hazardous Locations (North American)

Class I, Division 2, Groups A, B, C, D

Class II, Division 1, Groups E, F, G

UL844 Hazardous Locations (North American)

Class II, Division 2, Groups F, G

Class III

Other Marking/Rating

ABS certified

CSA certified: C22.2#137:1981

IP 66

IK 10(with metal wire guard)

Standard Materials

Applications

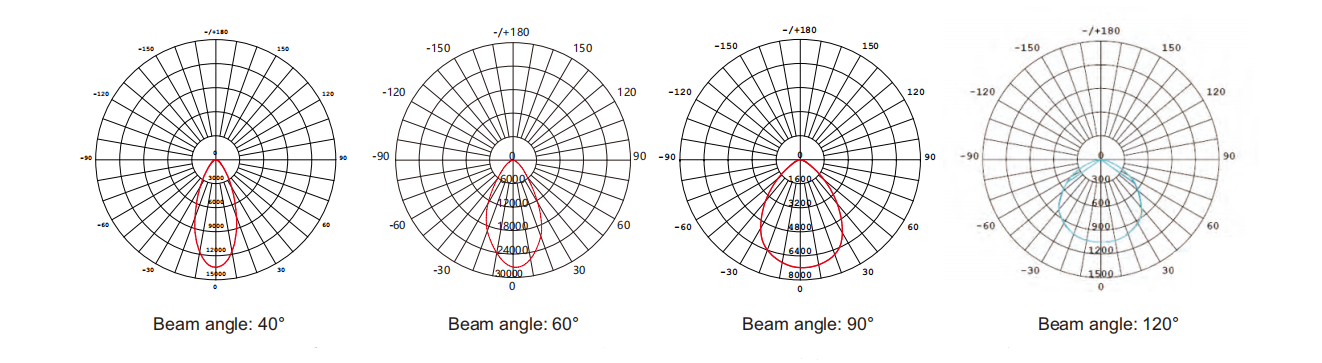

Light Distribution Curve

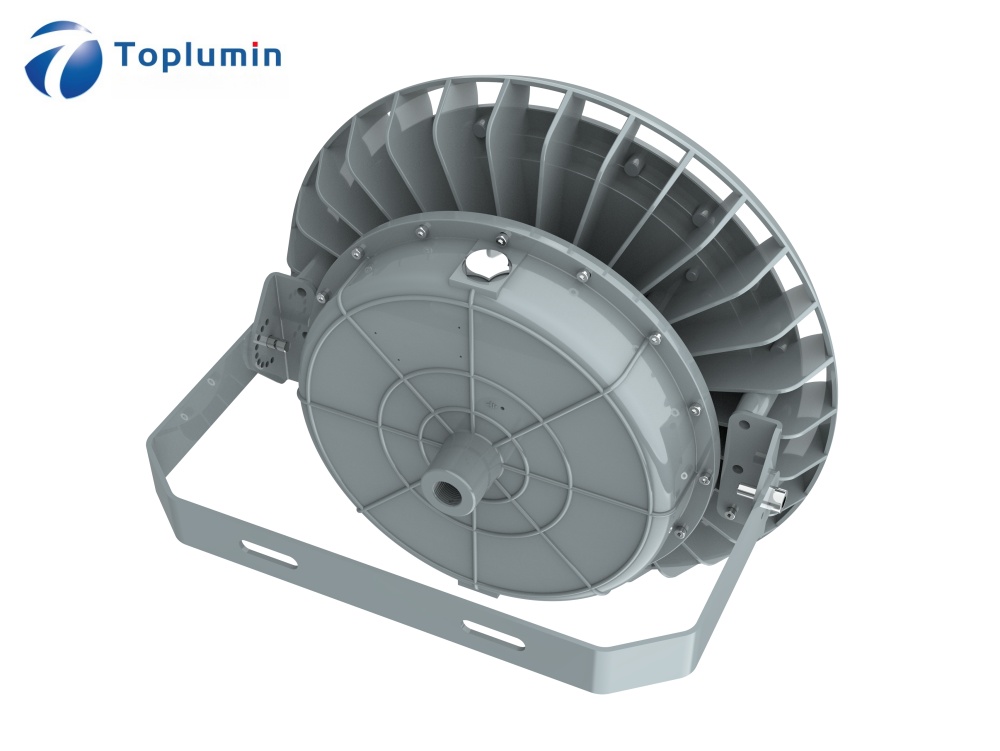

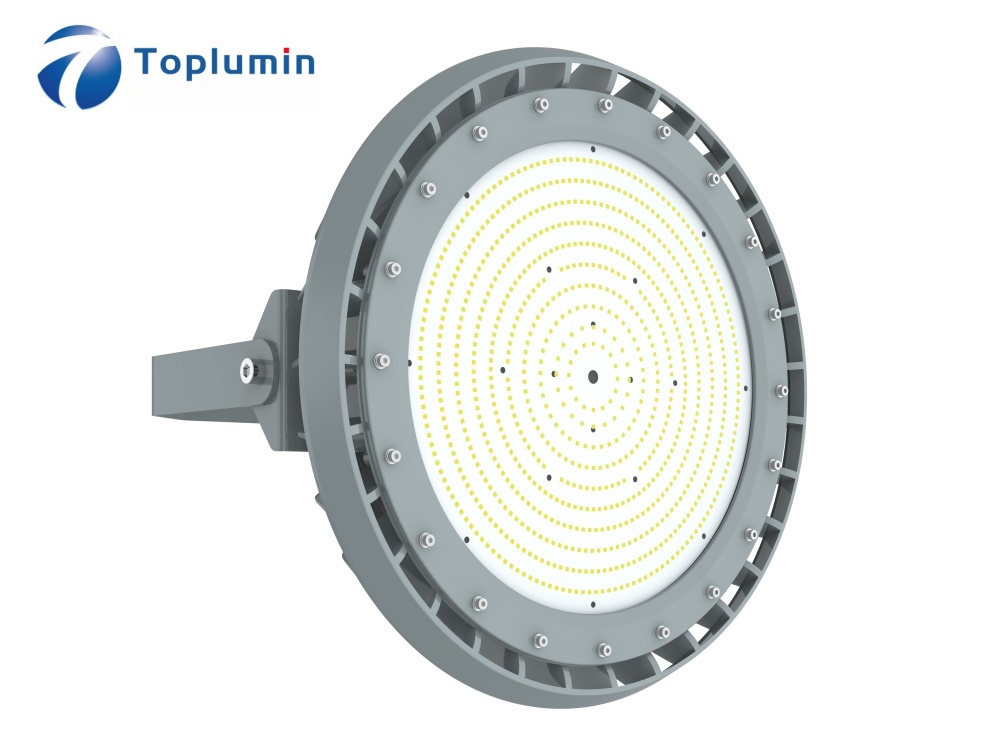

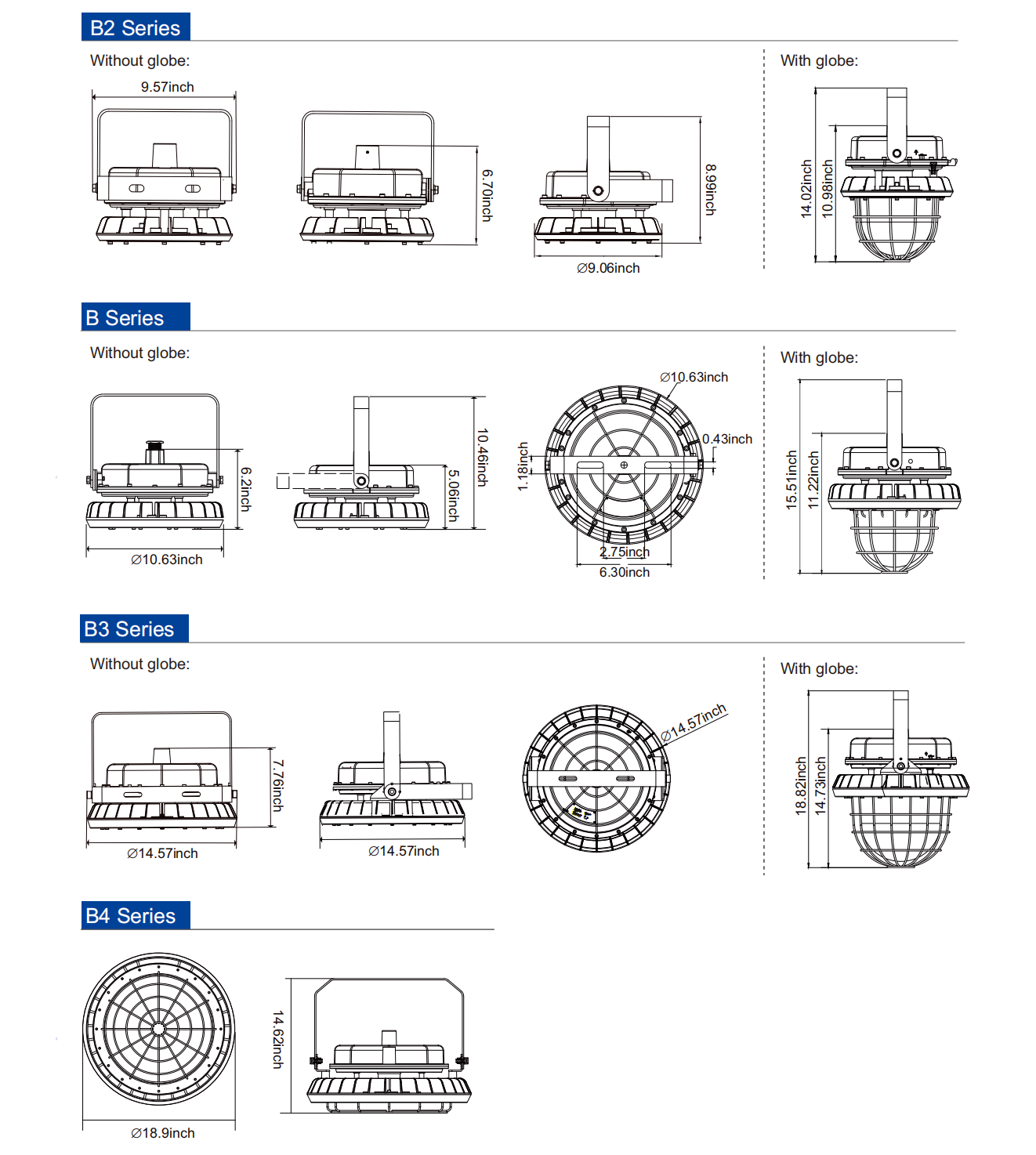

Product Dimensions

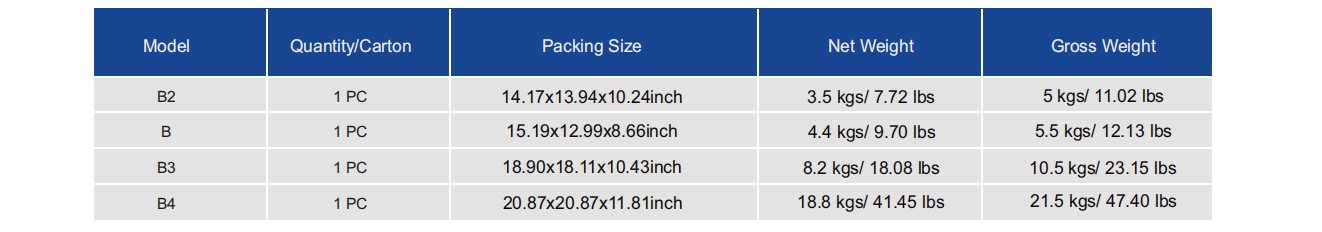

Packing Info.

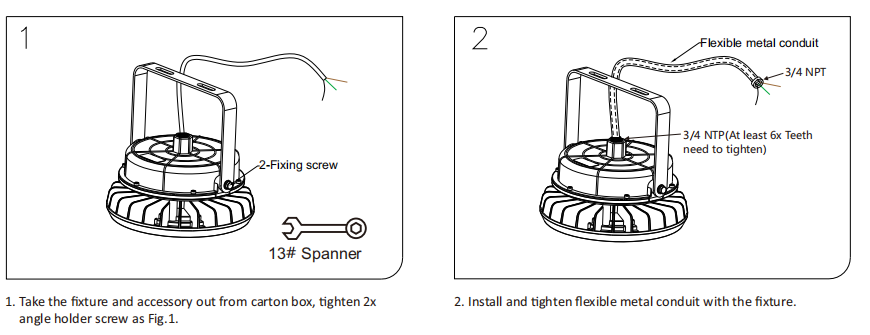

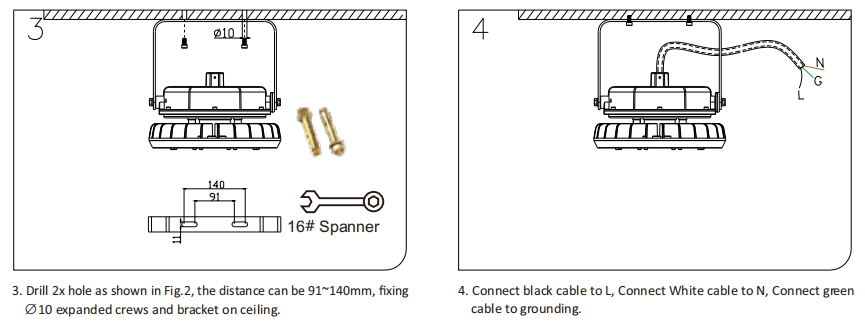

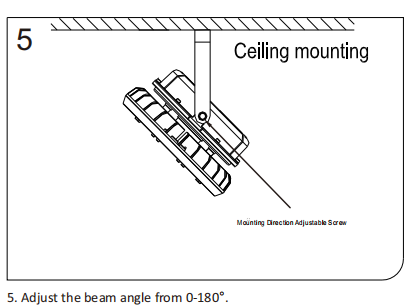

Mounting Methods

Note: For instructions of more installation methods, please refer to our product specifications sheet.

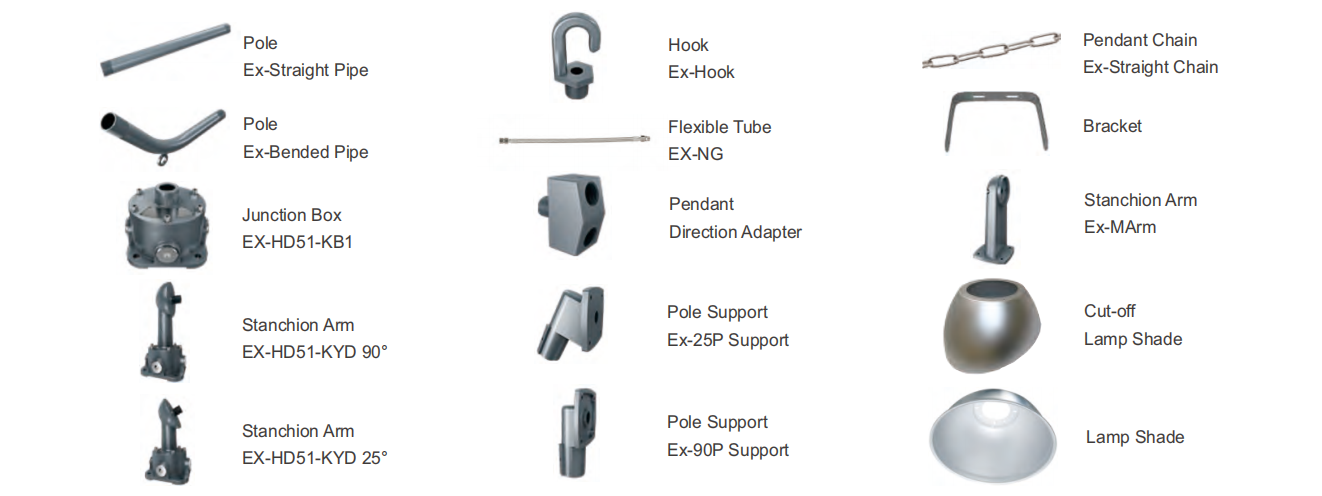

Accessories